I have always been interested in these types of sandblasters, because the most annoying part of this hobby is when the dust and abrasive involved gets everywhere. I never liked the feeling of having abrasive on my skin & hair- plus all over my clothes.

I haven’t used these vacuum on-site sandblasters, but recently I made my own and am selling them here. I figured a article would be beneficial to some people. Plus I’ll show you an inexpensive place to buy them below.

What Are They

Basically, a hose connects to the nozzle area so it vacuums all the abrasive & dust after it hits the glass. Then it’s dropped back into the abrasive holding tank. The head of the nozzle is interesting because it is made of brush type bristles that surround the tip in a circular fashion. I have thought about making ones of these before because they are kind of expensive, but I recently found an inexpensive one that I wanted to share.

Inexpensive On-Site Vacuum Blaster

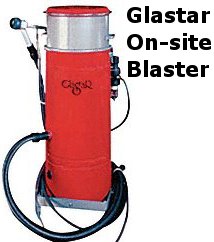

Quality Glastar Version

Lately, I found another brand by Uni-Ram here which seems to be of similar quality and slightly lower in price for about $1,600.

I hope this information is helpful and maybe it will save you some money. Has anyone had experience with these? If you have one of these units, leave a comment below. Or feel free to ask a question. Thanks

Share this on social media or email by clicking below!

I have made my own vacuum recovery unit for onsite blasting based on a cheap pressure pot. You can see it on my facebook page http://www.facebook.com/etchworx. It is not as compact as the ones above but can achieve much deeper etching.

Barry, that’s really cool! I am thought about making one, but was going to use a cheap siphon system and convert a small vacuum into the holding area.

I am getting ready to etch 28 windows at the worlds largest Masonic Center. This info could not come at a better time. THANK YOU!

Hi Eric, I never had a job onsite etching. if there is a marked for i would invest in a slide true cabinet with a dustcollecter with a one micro bag the same i am using now on mine cabinet. i have 2 cabinets so i dont have to change grid. also i am 88 years old and not so mobile anymore but verry interested in glass etching and blasting. william

Eric, thanks to your book I took up the etching and the sandblasting – I brought a compressor and a cabinet. I really enjoyed doing this until the material started leaking out of the back of the cabinet making a black mark on the wall and the black material “spilling out”. Please is there any way you can advise me of what I could do to still use the equipment but to be able to get rid of this problem. Thank you. It is a wonderful feaaling when you can give a personal one of a kind gift to someone and I would love to continue. Thank you Carol x

Carol, I totally agree. Personalizing a glass is the best part of this hobby.

I would get a dust collector hooked up to the cabinet and seal the leak. A quick way would be to duct tape it shut.

Thanks Eric. I was also looking at your article on the 28 gallon abrasive sandblaster with vacuum on Amazon, but cannot see anything on the UK Amazon site. Please could you advise me if you know of anywhere else in the UK that would sell them. Thank you x

nice work . I like it

Hi ur blog is very informative…good job…

steadblast.co.uk

the question is whether these machines require a separate compressor?

Hi Jorge, yes- they would require a compressor. These units are just the sandblaster. The compressor line would connect to these units.

If you are speaking in regards to the vacuum- the answer is no because that vacuum motor system is on the unit.

Does anyone have Barry’s design for vacuum recovery unit for onsite blasting based on a cheap pressure pot. The facebook link is not working now.

i need to buy this device and ship it to Jordan – Amman .

how much it will cost me?

is it useful for heavy duty work ?

is it useful for mirror and glass?

please contact via whats up 00962798367737