Sandblasting Glass & Sandcarving with Abrasives

A.K.A Abrasive Etching

This process uses a sandblaster and an air compressor to power the system which blasts high pressure abrasives onto the glass. The hard abrasives then lightly chips the surface of the glass to create a frosted look. The longer you blast, and the higher the pressure, the deeper the exposed parts of the stencil are etched into the glass.

Sandcarving

With the sandblaster’s high pressure characteristics, you can achieve what people call glass sandcarving. To sandcarve glassware, the abrasives are blasted at a very high pressure which carves deep into the glass. This process can help you create 3 dimensional etchings when used with staging techniques. A common practice is to look at this sculptured glass through the backside.

Above is an example of a quickly blasted mirror design of a Toucan. This was done with a simple two-stage sandcarved technique using the inexpensive equipment and a stencil design taken right from the internet for free. I show you this in my information resource. By the way, this example is an easy, quick, and basic two-stage etching that anyone can do. With a little more practice and technique you can produce marvelous works of art. Also, this design is basic but is still unique.

Sandblasting verses Etching Cream

There are many advantages to use the sandblaster method in comparison to the acid cream method. One of the most desirable advantages is it produces a sharper and more noticeable frosted appeal. Since, the sandblaster actually chips surfaces of the glass, the etchings stand out more and look very elegant. On the other hand, cream is more for the casual hobbyist and creates a less noticeable etching.

Most people chose the etching cream method instead of the sandblaster method because sandblasting equipment is expensive. When you use cream, you only need a few supplies which are very inexpensive.

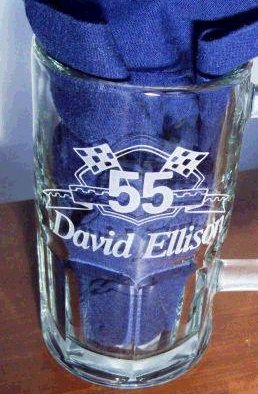

Here are some other examples of beer mugs made by sandblasting the outer surface. Let your creativity show and create a gift for someone on a shot glass, beer mug, mirror, shower door, window, or anything you desire. The possibilities are endless.

Share this on social media or email by clicking below!

Hi Eric. Can you direct me pls to where I can find a good complicated picture of a good old 1950’s British steam engine and coal tender, possibly with a carriage to sandblast.

I want to do it on black glass and I can adapt pattern for a negative image.

Thanks in advance. Brenda

Thanks for the information. I’ve been hearing a lot about sand blasting lately. I’d really like to know more about it, though. Does it always turn out well? Judging by the pictures you’ve shared, especially of the cup, it looks like it does!

Hi Eric Do you know you are doing a great job by informing us on the glass activties.any way am a glass artist i recycle glass waste but its not easy to handle in uganda.i need surport.

OLA

ERIC .Boa noite gostei imensamente este trabalho ,gostaria de aprender parabéns pelo trabalho.

OLA ERICBOA boa noite ,gostei imensamente deste trabalho .Gostaria de aprender este trabalho ,parabéns e obrigado por ter me enviado estes vídeos.

Hi,I would like to buy a starter micro sandblaster but don’t know what kind.Would like to know about scm jet stream one or profitable hobbies micro blaster ,if you can tell me anything about these or suggest one for me.These are expensive,and this well be my first sandblaster and first time doing this.Would like to buy everything i need to start( ex)film,grit,compressor size etc.Thank You

I love it, fantastic

Hello

Could you please, please tell me what abrasive I should use to frost a larger area of glass?

Many years ago We used stencils, an air compressor and it’s sandblasting attachment (Similar to this one: amazon.co.uk/Sealey-SSG8E-Economy-Sandblasting-Nozzle/dp/B000RA126Y/ref=sr_1_32?ie=UTF8&qid=1436016713&sr=8-32&keywords=sand+gun) to sandblasted farm animals onto the glass panes of our kitchen door, but I can’t remember what type of abrasive we used to do the job.

We now want to use the door as a bathroom door and need to completely sandblast over the animals so that ALL of the glass is frosted and non-see-through.

I have spent hours online trying to find out what abrasive to use on our glass, but everything I have found on sandblasting glass does not specify what TYPE of material to use!!!

Could you also suggest WHERE I can buy it please? (I am in the uk. cheaper the better)

All and any help will be greatly, greatly, greatly, greatly appreciated. Thanks you.

A Smith, I usually suggest aluminum oxide or silicon carbide, but since it sounds like you won’t be reusing it much. So a good choice would be Garnet abrasive. It is much cheaper too. I am not sure about the best place to buy it over there.

I have just ordered some Garnet abrasive from ebay. I will try it as soon as it arrives.

Thank you so much for the help.

Garnet abrasive did the job just fine (-: (Once I remembered to clean out the nozzle on the sandblaster gun, silly me).

Thank you so much!

Try Amazon they have a mirco sandblaster every thing you need is in kit even the abrasive grit.

Eric

In your foot pedal video you keep mentioning a kit but I have failed to find . Do you sell a kit or just the plans?

thank you and keep the videos coming, great stuff!

@Michael,

I was going to sell the kits but only started occasionally selling them when people request them and when I have time to put them together.

I love the work you show. I would like to start sand blasting and sand carving. Plerase will you give me some advice as to equipment and materials to buy.

This information would be most valued by me.

Thank you

I am a new starter and I love your work. I wand to start sand blasting and sand carving

Please will you advise me as to the equipment and materials I shoud buy

I will really value your advice

Love your work I done some lizards horse swan on pond. I worked for wauthrong aboriginal glass company. They on net . What would it cost to start . Sandblasted tools etching ect

Hi, William

I have a Profitable Hobby Micro sandblaster kit I would like to sell. I have only used it a few times. My husband wanted to do it and then he lost interest in it. I am an engraver and I don’t want to sandblast. I can sell you the hole kit for 1/2 off of there price plus shipping. If your interested just replay with an email.

Thanks

Elena

or replay on this blog I will try to keep up with it.

Elena

I think your work is fantastic. I have been sandcarving glasses for about two years now as just a hobby. I’m interested on how you make your stencils. I’m afraid to spend money on fancy machines that will not achieve what I am looking for. Do you have any suggestions or hints? Thanks.

Sam

I am a new sand blaster ppl and I am wonder what a safe pressure

For sans blasting would be? Lol I am sandblasting a reasonably expensive piece and would like to make sure I don’t just “shatter” it in my hands lol thank you and have a great day🙏🏼

I sent this to you in September

PLEASE WILL YOU GIVE ME SOME ADVICE

I am a new starter and I love your work. I wand to start sand blasting and sand carving

Please will you advise me as to the equipment and materials I shoud buy

I will really value your advice

I sent this to you in September

PLEASE WILL YOU GIVE ME SOME ADVICE

I am a new starter and I love your work. I want to start sand blasting and sand carving

Please will you advise me as to the equipment and materials I shoud buy

I will really value your advice

Hi I was wondering what type of machine and style of sand or glass you are using for your etching. My husband and I did glass etching and sand etching years ago in highschool. I use to know what brand equipment we used but have since lost that information. We would like to pick up the information again to start up for a hobby. Any information would be great.

Thank you,

Summer

I LOVE THIS. PLEASE I WOULD LOVE MORE INFO ON HOW TO ASSEMBLE MY COMPRESSOR TO PRODUCE REQUIRED PRESSURE FOR THE BLASTING AS I AM NOVICE MECHANICALLY.

Hi! I have all the equipment and have sand etched my first project. Problem is I can see small imperfections. I used small circles. Should I have used long one directional strokes instead??

@Shanna,

Are you referring to deep sandblasting or light? Let me know and I may have some suggestions depending on the type.

@Elena,

Can you tell me why you’re selling it?

I have a heavy sand blaster that I use on metal can I reduce air pressure and use this on glass, flat glass? Also, what pressure would I use.

@ Richard, you definitely can. The pressure really depends on how deep you want to blast but I usually use about 50psi.

Hello Eric – thanks for all the info!

I am a teacher who wants to do science and art projects using the abrasive blasting, and was looking at a cabinet or sturdy tabletop unit. I will need a compressor as well. For science, we would blast rocks to see the effects of weathering, and in art class, we would create frosted glass designs. Obviously, we don’t need a massive unit, and we have about $1000 to spend on the project.

I have been researching for days, but the options are really numerous. Can you please offer any advice to me to propel my project along? I appreciate your assistance!

Hello Eric my name is Ciaran and I do personalised gifts with sublimation methods I am now adding sandblasting to my services I have everything in place it’s just I have some ceramic nozzles that came with my cabinet so which one is the best yo start as I will be doing glass and slate etc and what pressure do you recommend thanks Ciaran

Perfectimagegifts

Has anyone used the Vaniman master pro blaster and if so can you get any carving depth with it, thanks for any feedback

Hi, can you please give some info on a set-up for wood carving?… I.e. cabinet and compressor. Thanks

lots of valuable hints being a former waterford crystal cutter i can now make new inroads in a new area

Hi Eric can you tell me witch kind of sandblasting they use as i think is not just sand, Because

here you mansion two type of sandblasting as aluminum oxide and silicon carbide, I need to

know the one witch is good for glass and mirrow, From Elna i want to know how much she

would like to sell that micro sandblast kit. I mean better price for black man from South Africa not

expensive because i am poor i just want to do something good.

Where can I find stencils for these kind of projects

@ Rick, most people have to make their own stencils for sandblasting and I only know of reusable stencils for very light sandblasting- those I provide but I still need to list them on the site which I hope to do within the next week.

@Robert both types of abrasive work just great- but silicon carbide lasts longer and since it is harder, should engrave slightly better.

Can sand blasting be done on 4mm glass?

@ Cecilia, you can certainly sandblast it, but I wouldn’t suggest going very deep. Surface etching would be best.

Hi guys !!

I really need basic information on sandblasting. I really want to start sandblasting but a bit scared because all know is the wild idea about it all. Please help me

Where’s a good place to get stencils? Such as C reds

Can these types of projects be blasted with the garnet abrasive ( have a good supply of it). Or do you recommend the other two abrasives you mention over the garnet? Would want to be doing mostly glass or mirror. Any comments would be appreciated, thanks. Really like reading your articles.

Hello, I am doing some research on the costs involved in glass etching. In this area I know very little and I haven’t been able to find anything substantial. Do you know where I can find this information? I need to know the basic costs for each type of etching. Thank you so much for taking the time to consider my request.

I can tell you that when using photosensitive resist, like those that Ikonics Imaging and Razist sell, you’ll be told it will cost around .06¢ per square inch to create masks. Not quite accurate. That’s the cost of the mask, but since you have to have some level of border all the way around your image so you can safely tape it off, you’ll spend more. Furthermore, you have to account for errors and the fact that you can’t expect to fit an image perfectly on available scraps, so if you’ve got a 6″ square image but only 5.9″ of contiguous area, you’ll have to break out another sheet. You’ll always end up with waste, driving up the cost per square inch. Still, it’s the best solution for clean masking of images with fine details – short of a multi-thousand dollar laser, and then you still need laser mask, so expect additional costs. I know that doesn’t answer the question or provide much encouragement, but it’s important to realize these facts before continuing along this career path.

I’ve just started using a dremel to etch glass pieces. I’ve been practicing and watching various videos to get info on techniques. I came across your site looking for a stencil to use. I chose your hibiscus stencil and would like to find more floral designs. Thank you for your help.

Good! Lots of likes for you etching secret. I want buy large whale inverted and blast windshield so go to beach and enjoy the view! Fun no? Where to buy template? What type compressor needed? Its for a 1985 Toyota Crew Cab. I am waiting response since September 2015. Must buy material soon. Aging fast. I have been told no playground material sand as give cirrhosis in lower lung abdomen. True or false incorrect?

I am a new starter and I love your work. I wand to start sand blasting and sand carving

Please will you advise me as to the equipment and materials I should buy and about how much it will cost me to get set-up.

Also I do a lot of wood work can a sand blaster be used to sand wood? I make Christmas Ornaments and Jewelry out of Cherry. We cut them out on a CNC machine (ShopBot). The part are small and its hard to get the sanding done. Can you advise me on sand blasting wood. and do you have any classes on sanding wood.

Thank you

Tim

I will really value your advice

such an amazing article thanks for sharing this information.

So glad i read this info. Have done etching with the cream! Is there any way to make it deeper or darker? Also, I have a compressor, and am looking to buy an engraving/etching tool. Any suggestions on the best ones? Thanx. Pat