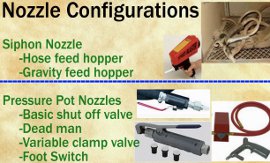

There are a few different types of nozzles that you can use to sandblast your glass. If your using the siphon sandblaster, they’re all similar except some are “on/off” types, and others have variable abrasive flow. The variable abrasive flow siphon nozzles are usually preferred over the on/off trigger type because you can control the amount of flow coming out.

I can suggest what will most likely work better, but it depends on your own preference and what technique you’re going to be using. The ebook and membership area here talks about these setups, and it explains where you can get low cost setups. Here is a list of some of the nozzle setup configurations that you can use:

- Regular On/Off Shut Off Ball Valve- This is a simple valve that you turn on and off. Usually, the basic nozzle setup is provided when you purchase the smaller sandblaster units. It’s the nozzle setup given on the 20 lb and 40 lb pressure pots from Harbor Freight. I don’t particularly like it because it requires two hands to adjust the abrasive, and it wears out quickly.

- Deadman Valve- This is another inexpensive valve, but can be turned on and off slightly easier with only one hand. Basically, it’s a spring loaded valve where you have to squeeze and hold down the trigger for sand to blast. You can find them for 20 bucks. The only thing that I don’t like about them is they are hard to keep open for a while since its spring loaded. I used it for the video on the basics of sandblasting

- Variable Clamp Valve- These can be very inexpensive, and they help you control the amount of abrasive easily from your fingertips. My plans are here, and you can pick up an inexpensive clamp in the at this source: tinyurl.com/variablenozzle. You can usually pick them up at a wine or brew supplies shop. They allow you to control the amount of abrasive and is ideal for shading techniques.

- Foot Switch Valves- These can be more expensive and some experts suggest the internal parts wear out quick. This setup can make sandblasting very easy to operate though, and allows you to focus more on your etching inside a cabinet. It allows you to turn the abrasive flow on and off easily from your foot.

- PAB blaster- The PAB blaster is a revolutionary variable trigger that many people say is worth every penny. It’s an expensive nozzle setup, and allows you to control the amount of abrasive similar to the variable clamp valve, but is more comfortable to use with a nice trigger setup. The parts do not wear out very quick because the hose gets pinched down. Every once in a while you will need to replace a small section of the hose. For artistic work, it’s a must have. You can order it from the manufacturer or make your own as I have done in this tutorial.

- Standard Siphon Nozzle- This is an on/off valve that is very inexpensive for siphon sandblasters.

Share this on social media or email by clicking below!

Eric, You used to have a video on the site of a home made gun you adapted that worked like a variable trigger gun.

You were going to post a how to on making one.

I can no longer find the video on the site nor can I find the How to.

CAn you please re post both as I would like to make one for myself .

regards

tony

Hi Tony, sorry I haven’t got around to it yet. I placed the link above for the video so others can find it as well.

I am glad you asked to because I made some mistakes above which are corrected now.