I need your help! I am always looking to make innovative sandblasting equipment (like some of the stuff I showed here), that is not only affordable, but something that also works better.

Recently, I had an idea of making a pressure pot foot switch which works somewhat like others, but can hold up to higher pressures, last long, allow variable pressures, and be about 4 times more affordable. If you are unfamiliar with this type of equipment, it gives you control over the pressure for both shading and sandcarving.

So I created my own sandblasting foot switch that I am thinking about bringing to the market to help people save money and have a quality setup. I remember when I started out many years ago, I was using a dead man valve! Boy, was that horrible and it would cost about the same price as this. You can see one of the foot switch prototypes that I made in the picture below.

Now- I would like to give one away to someone for free in exchange for feedback. It would include everything such as the:

- foot switch with adjustor for higher pressures (obviously)

- hose adapter & clamp

- 10 foot long hose (this isn’t the cheap junk you find in hardware stores- it’s a abrasive resistant, strong flexible hose)

- Nozzle with tip

I have been testing this design for the last 2 months and tweaked it a few times with constant improvements each time. So far, I love this inexpensive thing and it works awesome for me. The design is very simple but works better than anything I have ever had for my pressure pot.

I will pay for the shipping and everything, but I plan on giving only one away. All I ask is that you give me feedback. I would like it to go to someone who would use it often and could benefit from having it. Remember, this is only for people who have a pressure pot sandblaster!

Raffling The Foot switch Out

I figured it would be fun to create a raffle for the free foot switch. To enter, please just leave a comment below and I will run the raffle through a Random Number Generator.

Also, in the comment, leave some feedback on what you think of this foot switch idea. Do you think it would be marketable? Is it something that you would be interested in? Also, how much do you think people would pay for this?

Update: The raffle entry will end on February 7th next week at 5PM eastern and be for the US only. Sorry it’s been taking so long. I wanted to include everyone.

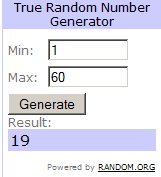

Thanks everyone! What I did was remove all my own comments and all the people that didn’t qualify because they either didn’t want it or weren’t in the US. I even created a pdf with the list here. (I don’t know why I did it. I am sure no one really cares that much, but I just like to be fair). I then used a online random number generator based on that list shown below.

So congrats Johnny Gordon

Share this on social media or email by clicking below!

I would be interested in trying it…I have the PabBlaster but do not use it as it is not reliable for me. I use just a regular pressure pot and foot pedal from Glastar and it works great. I am always looking for less expensive ways for replacing equipment.

@ Alyson- great! What is unreliable about the PAB? I have never had one but others say its great.

I just cannot seem to keep it working with an even flow of grit, it may be a humidity problem even though it has a huge drier attached. I like the control of the PAB gun, although after a bit it hurts my hand as it has a trigger control. I much prefer a foot pedal.

Well the grit flow sounds like a problem with the pressure pot, not the PAB, or is it?

I have heard that before about the constant pulling of the trigger. I made my own and it wasn’t too bad. at least it gives your hand a workout 🙂

How can anyone say that the PAB gun isn’t reliable !!!

Anyway, Eric, I am in the UK. Will the raffle include overseas members?

Tony, that is a good question. Let me check the costs for shipping over there the next time I go to the post office. I don’t plan on shipping this for another month or so.

Eric, I would love to try your new footswitch. I also have a PAB Gun and have found that my one disappointment is that I can’t raise the pressure. I have popped the hoses as well as the gun a few times. A footswitch would be awesome as I hold the gun so long during the day that it seems to be in that position through the rest of the night.

Thanks for this opportunity to try it out and give some feedback.

I would like to try it. Would I be able to use it for stone?

Thanks.

Bill

Eric……..I made one similar to yours only, it’s mental. It works fine.

Doug

Cool! I figured someone else had to make one of these also. Mine is also metal- it’s just painted black.

A device that can give a steady flow and control that won’t wear on the flangies and metacarpals FINGERS! would be a step in our field that we haven’t seen in a long time. It should really open up the artist and and a new angle to sandblasting that many folks in the trade have only dabbled in. Whether I get chosen or not, if your invention gets produced I want it. Thanks for constantly testing the bounds of our field. YOU THE MAN!

Eric,

Looks like a useful option for pressure pots.

I’m in Ireland and imported a PAB system quite a few years ago now. I really cannot fault it although I can see how holding the gun/trigger for extended periods could be a problem for some.

If you can stretch across the pond include me if not keep me posted as I might be tempted to buy such an add on at some stage …..

Regards,

David

Hi Eric, I’m interested in better control also.

would love to evaluate your foot switch for you

I have been using my pressure pot for blazing over 14 years now. I never tried a foot switch due to the pressure limitations. I have always had to adjust things on the pot or the air pressure to get desired results and this is a headache as I always need one hand near the valve to be adjusted……often with innacurate results. Would love to give yours a try. I work with a very wide assortment of substrates, but mostly I am working with glass, HDU foam board, or wood. A pedal having high pressure ability does indeed have it’s place in the market…..and doing what you are here will certainly generate interest! If I am not the person that has the honor of putting it through the test, make sure I get the info on it so ii may inquire if you do produce it (please). Thanks! Doug. 850-528-5772

I’d love to give this a try. In any case I’ll be watching to see what the feedback is, if it works and is affordable I want one!

It’s all getting exciting, maybe the trial should have units for UK,Canada and the USA 🙂

This foot switch would be awesome. Please include me in the raffle. Keep me posted too on your progress with marketing this foot switch. If it is reliable as well as affordable you should do well! Good luck with your endeaver!!

Cathy

Count me in, looks good, if its as good as the pab gun I have it shouuld be awsome

Steve

Count me in on your early sales list. I will be purchasing my system soon and would love to buy one of your early production runs. You could sell them as demo models (as is) . In exchange for a fair price the buyer would make his comments known to your as part of your research and development stage. Consider making a few and giving your fans a chance to be in on the ground work

Dave

I made all of my equipment… except the compressor and hoses, of course. I use a valve with a handle and would like a food pressure switch, but find them too expensive. I’ve sandblasted glass since 1982. I’m getting a bit long in the tooth, but would love to win something like this. It would make my work much easier. You might also sell the plans. I purchased plans for making a glass cutting machine for cutting strips. It isn’t done yet, but will be soon. If you decide marketing might cost too much… and it does cost a lot. You might consider registering your work and selling the plans… just a thought.

Hope I win!!

Thanks everyone for your suggestions so far.

@ KaCe, I will most likely make plans as you suggested and have already been thinking of that. I really don’t think there is much of a market here to be worth spending time into, but I will offer them for people that can’t make them their selves. At least that way it will help some people out.

Robert

I don’t want one ,but i will give you some advise.!!!! Patent it !!! Once that leaves your shop you don’t own it anymore. Say you send me the unit, i could put a patent pending on that in a heart beat and only i would receive royalties, or even sell the patent plus i get all the credit for your design, and you would be out in the cold and penniless with no recognize for creating the product. Cancel this give away and start with a seeing a lawyer or do some homework on getting it patented. I do hope you take what i said serious

I have used a foot pedal for years and it has been problematic with leaks, pressure, etc. I would love to try your foot pedal and if it’s an improvement, I will be your biggest fan.

Thanks!

I use the pt100 cyclone pressure pots with there foot pedal and have had no problems with them for years now. I would give an honest feedback so I will inter the raffle. thanks for the email

I have been using a pressure pot for years (actually bought plans off you years ago!) but have been using a type of foot pedal device I came up with using a hinge and piece of dowling…. problem is that the flow is restricted while I am pressing and after 15 minutes or so I have to break. Your design looks very interested and I would love to try it.

Doug

I would love to give this a try , sounds like a great idea

@ Richard Gottshall, thank you for the advice. It is a good suggestion, but I recently decided to not really make a business out of this because I don’t think there is a large enough market and the profit margin is small.

I will probably write up plans so others can make it themselves (bc it is really easy to make), but will probably offer a few of the low cost units for people that don’t want to make. That way it will help them out a little. If things really look demanding, I might change my decision later.

I would be interested in trying this foot switch out. This is a great idea, and would be very helpful when we are carving and frosting the same item. Thank you for the opportunity.

What great timing! The foot pedal on my pressure pot just quit on me. I’m blasting glass quite regularly and love the ideal of a low cost solution that I can easily maintain. Count me in- I’ll even discuss it on my blog so that all of my tens of readers will bear witness. (OK, so probably just my Mom and Dad. But I’ll talk about it anyway).

Pressure pot for more years than I want to know! Love to try it out. Have engineer backgroud if that helps

Jim

That looks very interesting. It would be a great help. Thank you for letting us know about it.

I’m not sure if I have the right sandblaster for this attachment (a modublast sandblasting cabinet) but if it does I’d be happy to be a guinea pig.

If this would solve my current problems I would be more than happy to provide feedback. I feel that all of us have a varity of problems with the quality and price of manufactures replacement or original equipt.

@ Krista, thanks for letting me know- as I would like this to go to someone that can use it. Is it their pressure blast or suction blast systems? They have both.

@ Tim, How much would something like this be of value to you? I am trying to make it an inexpensive solution as possible to help others out, but if it’s too low it would just not be worth my time- so I have been contemplating on just creating plans for the DIY’ers.

Being a product engineer, I would love to evaluate your product and give you feedback.

Been blasting for 7 years as a hobby, but has turned into a full time job would love to try and will give honest feed back wether good or bad.

Eric,

I have used a couple of different ones in the past with big dissapointments, too much abrasive, too much air, intermittance, clogs, etc. I would definitely be interested on knowing more about your product whether is a test, a final product for sale, depending on price or plans. I would not try to offend you with a low offer. You are placing a lot of your heart here. I would price accessible, most of us are hobbiest here but high enough to make you satisfied.

Hugo

Hi Eric,

when is the date of the give away please?

I have my fingers crossed 🙂

I would like to enter your raffel.

@ thanks Hugo. I know most footswitches have some problems like that but that sounds primarily an issue with the sandblaster itself.

@ Tony, I’m sorry to say but I don’t think I am going to include the UK- at least for now. I thought you had the PAB anyway?

Update: Oh, sorry. The raffle entry will end on February 7th next week at 5PM eastern. I will update the post with this info.

Would love to try one out.

Hi Eric, thank for including me in the raffle. i have never before work with a foodpadel with my pressure pot and would like to try it out. Unfortunaly I am very far from you as I’m in NAMIBIA, dont know if you know where it is. I think its i great idea, sound very good to me to have your hands free for doiing the job. All the best with your concept and I wish you luck. I’m also not sure what I will be willing to pay for it, because I have never use one before, and because I dont know your currency.sorry

Hi Eric

Sure like the info you have passed on so far, so I’m sure the new foot will be great too.

I basically gave up on a pressure pot system and bought a syphon feed hose and gun because the

foot switch on the complete package unit I bought only worked for a couple months.

So always looking for something better so I can go back to the pressure pot.

Ross

Hi Eric,

Yes I have a PAB but I also run multiple pots and a gravity fed cabinet. Shame the raffle doesn’t include the UK. Hopefully the plans will.

I don’t like the idea of a raffle. You should give it to someone that uses the sandblaster a lot and has good ideas about improving its function or manufacture.

I do like your plans and the idea of low cost equipment that actually works!

I just use a piece of bailing wire around the dead man switch to hold it on for long periods of time.

Gary

Id be interested in trying it out sign me up.

Hello Eric. I am using a foot pedal now but I am not thoroughly satisfied with it. I have to tweak it often, e.g. setting pressure, amount of media to release, to get it to flow like I need. Sometimes my foot pedal does not operate as it should. Constant have to tweak it. I do surface etching but mostly I do glass carving. I do think it would be marketable if some of the common things that occur with foot pedals is corrected and your marketing campaign can stress that and of the ease of operation. The price I would think might be good would be between $100 to $125 for a complete kit (maybe, not sure on that). I would be willing to try it and give back information that you could use in marketing your product and also for feedback purposes.

Hello Eric, I made two using mid size propane tanks and use them as med/fine and coarse. I used the clamps from the RV unit which held the tanks originally and welded them to a heavy duty dolly. I have several locations plumbed for air in my shop and have set up a primary space in a 20′ shipping container. I can recycle my abrasive here relatively easily with a drop sheet. I have a rail overhead with trolley rollers and a chain fall attached which allows easy in/out with large objects. I made a large “tank” with a window from a mobile home larger propane tank. I have tried various gun control and bought a cheap no name copy of Pab and real Pab. Still not where I want to be for control. Your project sounds interesting. Please enter me in your contest, keep me on your mailing list and much success with your projects. Thanks from Phill

Hello Eric, Would like to give that a try, put me in the raffle too. Thanks, Glenn

Hi Eric,

I live in the UK and have built my compleat system cabbinett and blast pot but the thing that lets my set up down is the controll and the trigger on the gun. I have been spoilt because I use a system at work with a foot control wich is 100% better.I have looked in to getting one the same as works but the cost is a bit high for a home DIY set up.I am not blasting every day but when i do I realy miss the foot cotrol. So finally I would be very interested in a foot cotroll and I like the idea of it been within my price range.

Garry

I like the foot pedal on my Rayzist cabinet but a variable switch would save time in having to stop and adjust pressure. Count me in!

We just installed a new sandblaster to use for engraving stone, granite, etc, it does not come with a foot control.So this would work great on it. My previous one has a foot control which I love.

Please enter me in the raffle.I definetly would give you feedback on how it would work. I agree with one of the other comments price around $100.00-125.00 for the kit would be reasonable.Good luck

I have been thinking of switching to a foot pedal switch on my pressure pot. I am looking forward to hearing how well yours works. Maybe you can post a video of it in use? Count me in on the free give away.

it would a great Add to my new pot blaster

Sounds like a neat idea, I would LOVE to try it.

Its nice am a glass designer down here in Nigeria work with various kind of medium on decorating flat glass. Keep it up

Eric, I would be very interested in trying your foot switch out in my home-made sandblaster. Please include me in your raffle. I really enjoy your site and blog. Plus, I was schooled to be a Industrial Education/Science High School teacher and commend you on your DIY spirit! It just blows me away that folks are either lazy, lack the motivation to make equipment and/or willingness to learn the knowledge and skills to make the equipment themselves. Keep it up Eric, you motivated me to make my own sandblaster so when I shut the hot shop down in a couple weeks, I will have the time to mask off the various glass pieces, platters, bowls, vases, mugs, goblets and hone my masking,sandblasting/sandcarving skills and hopefully try out your sandblasting foot switch. I will submit some photos of work that you can post on your Facebook or website.

Sign me up for the raffle.

Thanks

I am interested in the footswitch

sounds like a great idea!!! I would love to try one ! I could put it to the test and give feed back good or bad. Sounds like it would be good. If I win send it and I will start testing right away. If not send details and we will go from there! thanks Rick

Sounds like a good idea and would be interested in trying it out.

Would love to try a different foot pedal. It really is the only way to go and if you have a new design that is also cost effective for replacing old equipment then that’s terrific. You go!!!

I blast rocks as a hobby. I would love a foot pedal. I’m not a good chose for trying it out as I don’t blast much. If it works I would like to buy one.

A foot switch for a pressure blaster is a fantastic idea as I am also battling with the deadmans handle.

Eric,

It is quite interesting with innovative mind. Always work becomes interesting if you have control over it.I cant guess the price but as you stated early on the costing is entirely in your hands to be able to meet the demands of the people out there.

Definitely if I get the chance I would use it.

Thanks

Hi, Eric, y’know, I believe THIS is the only GUN CONTROL that makes any amount of sense at all. Gosh, I sure hope our Pres., Biden and the others don’t legislate against our Constitutional Rights of owning and operating our “blasting-media-assault-weapons-of-glass-distruction.” We really don’t need another OBAMASCARE thing. Anyway, Eric, if you would like an evaluation as to the overall utility, coupled with some real-world lab testing, the comparable reliability of your basic design as well as the marketing potential, production tooling and manufactured unit costs, then gimmie an e. That’s what we do. Also, if the product merits, we can show you how to immediately begin the stages of legal protections, forming a limited liability corporation with yourself only, or including several other members. Also, you will want to establish a hold-harmless-clause which can help greatly with potential consumer liability issues or complaints arising from individuals utilizing your sold products or even do-it-y’self plans. We can also find the investment capital necessary for making a strong product-launch possible. R. Allen Cook

Hi

Robert I am interested,is it real

thanks

suman

Hi-Eric.Are you planning to sell plans for this eventually.

Regards.-A.

hi eric

i do alots of sand blasting i would love to try it out .if it works good i dont think people have a probblem paying a fair price

joe w

I think that’s a wonderful idea, ingenious. yeah, if I had an opportunity to use it, I would give it a workout! wish you all the best on your project .

I’m up for the raffle. Please get this to market quickly as possible. I have 2 pots with different grit sizes and a foot pedal would be a God send

A good idea? How about a FABULOUS idea!

Yes, I think it would be marketable.

Yes, people will think it is a very good idea.

I would like to give it a try

Very nice! I love the knowledge I have gotten from you already, GIANT thanx from Oregon

I’m still just starting out ,I have a pot blaster,and It’s difficult with that much pressure.I would love to try that foot switch out.

Yes would like to try, See if it works down south.

Please include me in the raffle also… Looks like a great product to try out!

Always interested in someting that will make sand blasting easier as it is hours of work on a project and feet get tired !

So, who won the Raffle?

How have you been getting on with your prize?

Hi Tony, the winner is listed in the description. I’ve received a little feedback from him but not much. 🙁

Next time, I will probably just give it to someone that could/ would actually use it.

Are you the plan’s yet?

Sorry, are you selling the plans yet?

I kind of feel behind. I plan on writing them soon actually with in a week or 2. Sorry

I would like a set of your plans. Thanks

I would also be interested in your plans. May I suggest a resource list of where the parts are available? Those of us who use the plans can add to the resource list. That would make adopting the tool easier for later adopters of your plan. Thanks.

I do not see a “kit” available nor a price for it. Do you have a kit? How much is it? Do you know the approximate cost of parts? TIA

Eric,

I know this post is getting pretty old, but I still would love to see the plans for this. I’ve looked into a few designs, but this I believe would also work well for my soda blaster. Got them plans drawn up yet?

Woohoo, never mind, here is a video and a link of where to get the plans https://www.youtube.com/watch?v=7kgZzcOZLsc

Hello Eric.

Can I buy the kit please?

If so, how?

Kimberly