In this post, I will list some of the positive and negative characteristics for both sandblaster types talked about before. Remember, one of these are required in order to make your etchings look more advanced in comparison to the typical hobby cream. Below, I will explain the siphon sandblaster and its characteristics for abrasive etching.

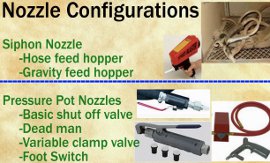

Siphon Setup– This setup has an air hose that connects the air compressor straight to the nozzle. Another hose is connected to the same nozzle that carries the abrasive particles. It basically works by siphoning the abrasive out of a container and thrusting it out the nozzle.

- Positive Characteristics: This is the cheapest setup. The major advantage is that some are manufactured with a nicer nozzles that allows better control to do advanced artistic techniques such as shading. The nozzle allows a variable flow of abrasive and air mixture with a slight move of your fingers on the trigger. Not all siphon nozzles have the variable pressure feature, but isn’t needed for basic etching.

- Negative Characteristics: It doesn’t have as much blasting power, takes a longer time to etch, limits the possibilities of multi-staging & sandcarving, and uses more compressed air to operate. Another disadvantage is its inability to keep a consistent abrasive flow. It is less efficient than the pressure pot which doesn’t usually allow the ability to do multistage sandcarving.

Share this on social media or email by clicking below!