I am restoring my old Porsche 911 from 1979, and since the aim is to make is as original as possible, I would like to know If it is possible to re-create original marking of the windshield. I will forward a picture of the original marking and look forward hearing from you. Thank you.

Kindly regards

This is a great question. I believe most windows are marked via a laser engraver but I am not 100% certain on the method used today.

So here is a list of ways that you may achieve this:

- Ask a Laser Engraver Shop– You could try asking a sign shop that has a laser cutter/engraver to see if their equipment can do this.

- Do It Yourself with Photoresist– Or the other method is to do it yourself by making a photoresist stencil and using either process:

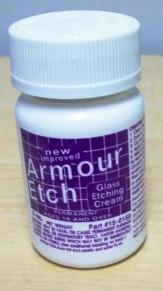

- Cream etching– most photoresist material sold today is for use with sandblasting. However, I have seen one manufacturer offer the cream etching photoresist. An alternative route is to use PCB stencils which is abbreviated for “Printed Circuit Board.”

- Light sandblasting– the photoresist widely available is developed with a thin layer that needs to be sandblasted.

Creating Stencil with Photoresist vs. Cutter Machine

Since Steen needed to etch very fine details shown in the picture, the photoresist is probably the only route that would develop those small, intricate letters, numbers, and designs. Most cutters can’t do too great of a job this small.

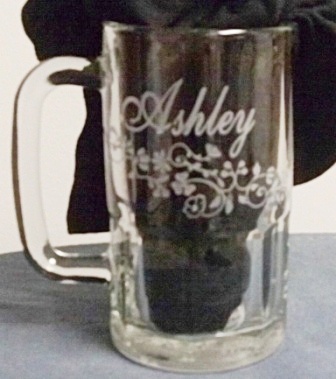

However, if your graphics are slightly larger, you may be able to cut an inexpensive stencil with a vinyl cutter. I created an example of the fine details the photoresist allowed me to etch in the top image here and some fairly intricate details cut out with the vinyl cutter in the bottom example.

Process of Creating Photoresist Stencil

If you can’t find the designs, you can take a good picture, import into your graphics software and either trace it or create an automated vector. I talked about that in the ebook with free software. Then you would need to find the right font and type the text in.

After it is designed, it needs to be sized in your graphics software (there is measurement marks in the software) and printed on your transparent film. Then it is developed on the photoresist.

Share this on social media or email by clicking below!

The photo resist is probably the best way to go because of small and fine details. I myself use this method for delicate and fine details. When using on car windows you would be doing a surface edged not to be engraved with dept just surface etched. And this method is sandblasted with low pressure and best recommended aluminum oxide fine grit of 180. By using low pressure might have to do a few passes to assure etching is being archived. If it’s only for a one time project I also would recommend blasting kit from hobby lobby. I hope this input is of some help. Gilly from ROYAL BLAST Sand-carved Images Dallas Tx.

Thank you for your info on etching or blasting on car windows etc. I have been wanting to get back into doing some of my etching on glass etc so this etching memo is just what I needed to do it again.

THANKS

Joanie Beck

Hi Eric, as suggested above, using photoshop to create a duplicate made up of vinyl sticker of the original design is I think the best alternative. Anothet is by using silk screen method. Then applying etching cream (please google etching glasses in 30 seconds youtube for procedures). You may also google olx.com devour etch fa etching cream for further referrence. Thanks.

It’s odd someone would ask this imho. Maybe I’m synical. Wasn’t that glass not road worthy? Don’t believe they used safety glass in Germany/Europe back then. So it would b a boon for anyone restoring a vehicle to use modern glass. This no way marks down the price or value of a restoration. Even museum restorations use modern glass, this I know from experience.

I used to cut glass with my sandblaster back in early 90’s. Was cutting modern glass to fit into old cars to update them to be able to run on modern highways. You couldn’t get your new restored vehicle approved without modern DOT approved glass. Not even with a Historic Restor license plate. And that plate allowed EPA regs to fly out the window, just as long as said window had DOT approval!

So yeah, you could fake the etching, and they used hydrophilic acid to etch using screen print. Your choice bro